PLC - Programmable Logic Controller

The automation of many different processes, such as controlling machines or factory assembly lines, is done through the use of small computers called a programmable logic controllers (PLCs). This is actually a control device that consists of a programmable microprocessor, and is programmed using a specialized computer language. A modern programmable logic controller is usually programmed in any one of several languages, ranging from ladder logic to Basic or C. Typically, the program is written in a development environment on a computer, and then is downloaded onto the programmable logic controller directly through a cable connection. The program is stored in the programmable logic controller in non-volatile memory

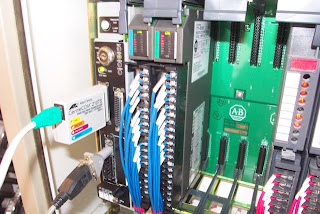

Programmable logic controllers typically contain a variable number of input/output (I/O) ports, and are usually Reduced Instruction Set Computer (RISC) based. They are designed for real-time use, and often must withstand harsh environments on the shop floor. The programmable logic controller circuitry monitors the status of multiple sensor inputs, which control output actuators, which may be things like motor starters, solenoids, lights and displays, or valves.

This controller has made a significant contribution to factory automation. Earlier automation systems had to use thousands of individual relays and cam timers. In many cases, a PLC allows all of the relays and timers within a factory system to be replaced with a single controller. Today, programmable logic controllers deliver a wide range of functionality, including basic relay control, motion control, process control, and complex networking, as well as being used in distributed control systems (DCS).

Digital signals yield an on or off signal, which the programmable logic controller sees as Boolean values, those with only two states: true or false. Analog signals may also be used, such as those from devices like volume controls, and these analog signals can be seen by the programmable logic controller as floating point values. This is one way in which a computer can represent a rational number, but can be imprecise

There are several different types of interfaces that are used when people need to interact with the programmable logic controller to configure it or work with it. It might be configured with simple lights or switches, or a text display. More complex systems might use a web interface on a computer running a supervisory control and data acquisition (SCADA) system.

Examples of plc programming applications that have been successfully completed and are in use today.

• Manufacturing Industry

- Lead acid battery plant, complete manufacturing system

- Extruder factory, silo feeding control system

• Travel Industry

- Escalator operation, monitored safety control system

- Lift operation, monitored safety control system

• Aerospace

- Water tank quenching system

• Printing Industry

- Offset web press print register control system

- Multi stage screen washing system

• Food Industry

- Filling machine control system

- Main factory feed water pump duty changeover system

• Textile Industry

- Industrial batch washing machine control system

- Closed loop textile shrinkage system

• Hospitals

- Coal fired boiler fan change-over system

• Film Industry

- Servo axis controlled camera positioning system

• Corrugating

- Main corrugators machine control system

- BOBST platten press drive and control system

• Plastics Industry

- Extruder factory, silo feeding control system

- Injection moulding control system

• Agriculture

- Glasshouse heating, ventilation & watering system

• Foundry

- Overhead transportation system from casting process to shot blasting machine

• Leisure

- Roller coaster ride and effects control system

- Greyhound track 'Rabbit' drive system